Bronze Nuts

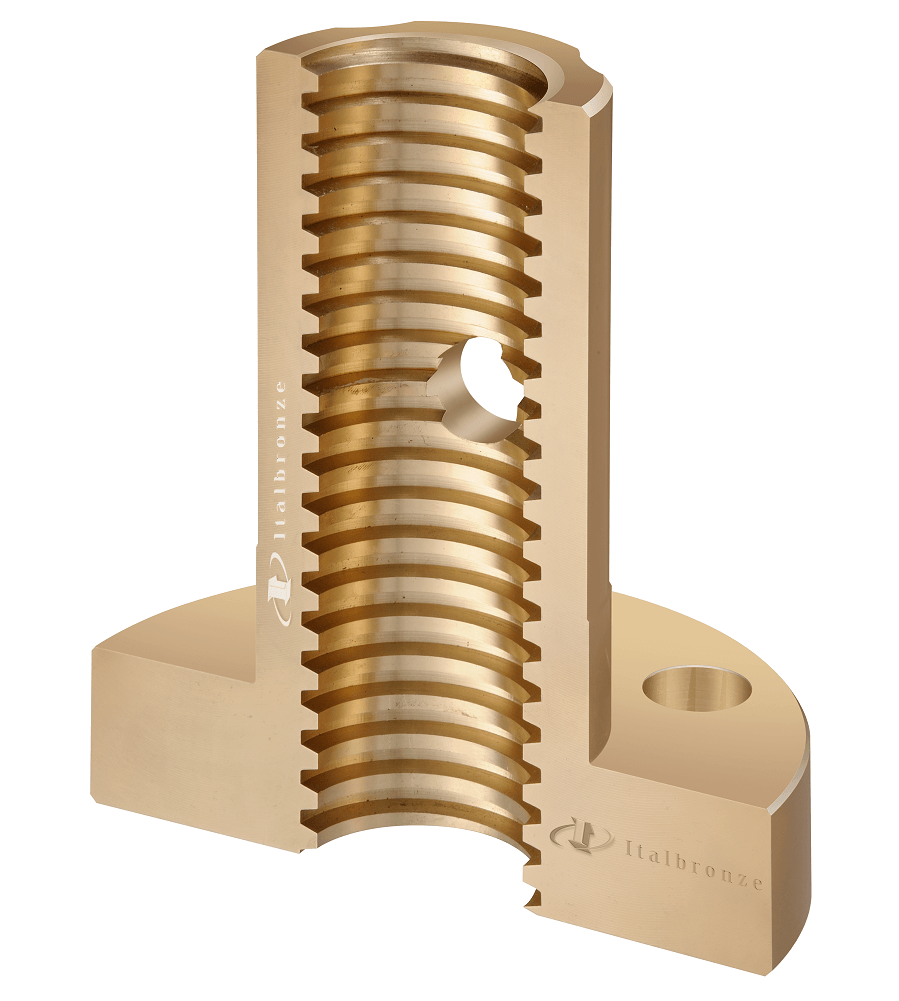

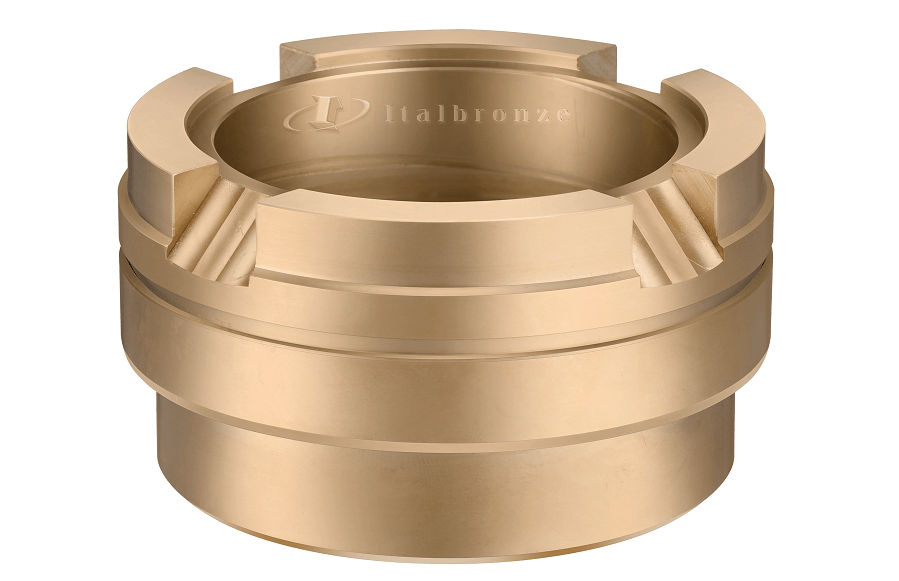

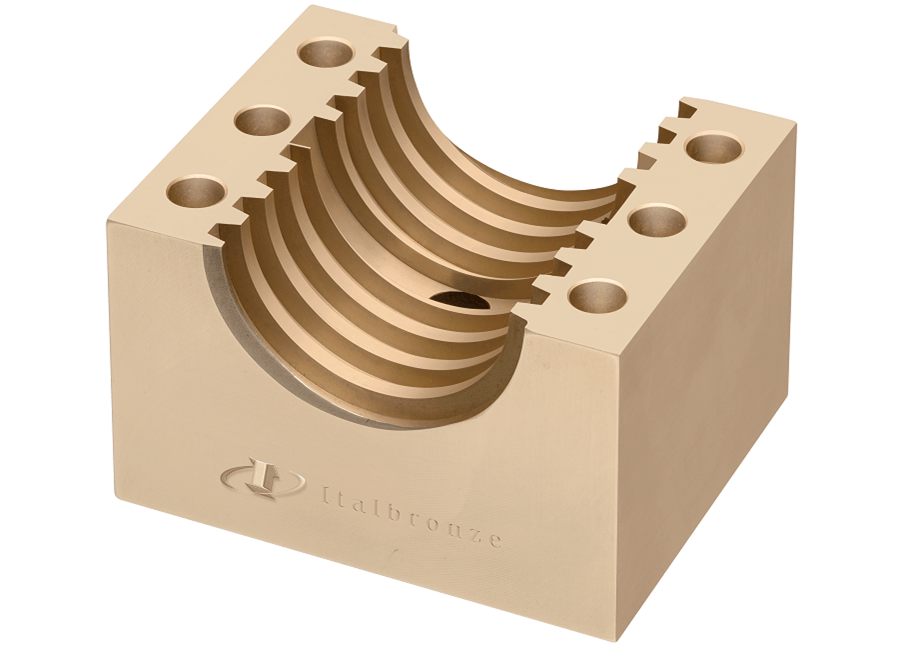

Bronze nuts are bushings with internal threads and with a smooth or staggered outer diameter, depending on its application. They are often employed in branches of industrial activities such as forging, laminations, heavy transport or mechanical drive systems.

In general, the nuts vary according to the threads and format, being the most common the hex, square, knurled, butterfly, auto lock and pressure nuts. Hex nuts can also be found in the versions with retainers, deformed fillet, or the nuts type applied on top of threads. They are also commonly used in the transmission of movements, as in lifiting jack in which the spindle rotates and the nut moves bringing the structure of to rise.

Italbronze’s bronze nuts integrate equipment such as mechanical lifiting jack, level bases, friction presses and steel rolling mills. Of the various applications that make use of them, the most common are:

- Nuts for presses

- Nuts for cylinder adjustments of the mill

- Guides of forging spindles

Various bronze alloys are available for customer choice, each suited to a specific type of application. The most frequently produced and made available are the high resistance, such as IBz55 and IBz63. The bronze which is used is fused by the centrifugal casting process, which ensures a uniform structure, and as a result, a product of high performance and durability.

Thanks to the high standard raw material, Italbronze’s bronze nuts offer excellent load capacity, good wear resistance and are less susceptible to damage from impact and shock loads.

Italbronze bronze nuts are produced with the highest technology, modern equipment, centrifugal casting process, and precision machining on CNC machines. The production process is recognized by ABNT and by national and international organizations, thus ensuring a highly reliable product.

One of the major differentiators of Italbronze’s bronze nuts is that it is produced according to the customer’s needs, with millimetric precision according to measurements provided.