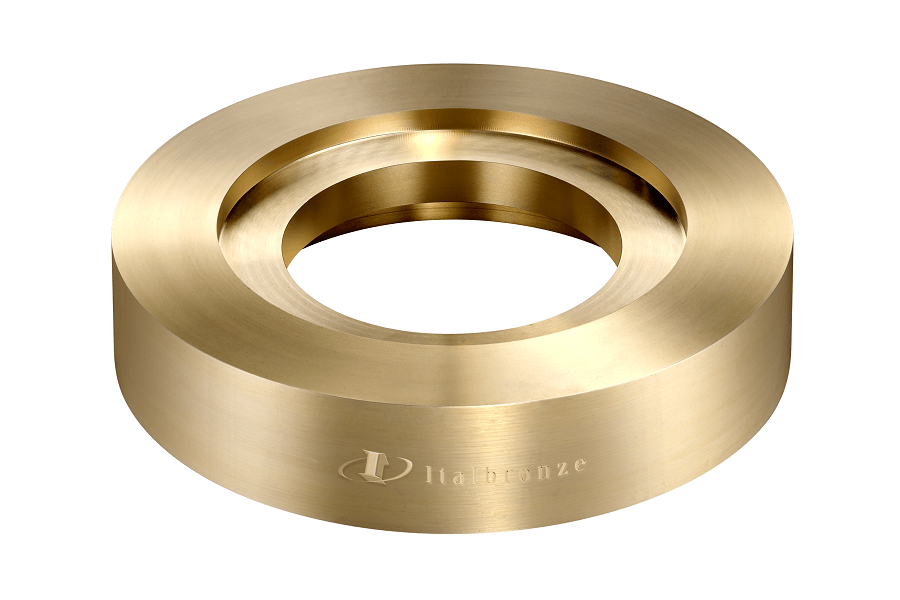

Bronze Crowns

Bronze crowns are rings casted by the centrifugation process in which the teeth of the part is machined . It is a component widely used in the internal gears of reducers and variables of speed. It is very common to find them in cranes, gantries, rotating bridges, elevators, variable speed drives, among others.

Italbronze’s brass crowns are produced with the highest technology, merged by the continuous or centrifugation process. The process ensures excellent peripheral quality to the bronze crown, increasing the life of its teeth and ensuring better performance and lower cost of maintenance of the equipment. The precision machining and finishing are made in CNC state-of-the-art machines.

Several are the materials with which the bronze crown can be made of. Metals or polymers are the most commonly used. It all depends on the purpose where it will be employed. The bronze has unique properties which have advantages over other materials used for this purpose, among others, the best cost-benefit ratio.

The technology and processes adopted by Italbronze guarantee a uniform structure to the products, resulting in crowns or other pieces of high performance and durability, qualified to meet ABNT norms, international norms, and standards of each country.

The differentiator of Italbronze’s bronze crowns is that they are manufactured according to the need of each equipment and intended application. It is manufactured in the dimensions that the client needs and with the most commonly used alloys available in the market, such as IBz-40, IBz-31, IBz-11, IBz-21, IBz-55, and IBz-63.

Due to the use of raw materials of high standard in their production lines, Italbronze’s crowns are usually found and used in various branches of industrial activities, such as;

- Iron and steel industry

- Heavy mechanics

- Power generation (hydroelectric)

- Mining

- Transportation

- Iron and steel industry